Industry Introduction

Ink is a uniform mixture composed of colored materials (such as pigments, dyes, etc.), connecting materials, fillers (fillers), additives, etc; Capable of printing and drying on the printed body; It is a paste like adhesive with color and a certain fluidity. Ink not only has bright colors, good printing adaptability, and suitable drying speed, but also has certain application indicators in solvent, acid, alkali, water, light, heat, and other aspects.

Ink is mainly used in the printing industry. Pigment is the main solid component in ink, and the grade of pigment, such as color phase, concentration, dispersibility, and physicochemical properties, directly determines the tone, color, clarity, and other aspects of the image on the printed product.

Product Application

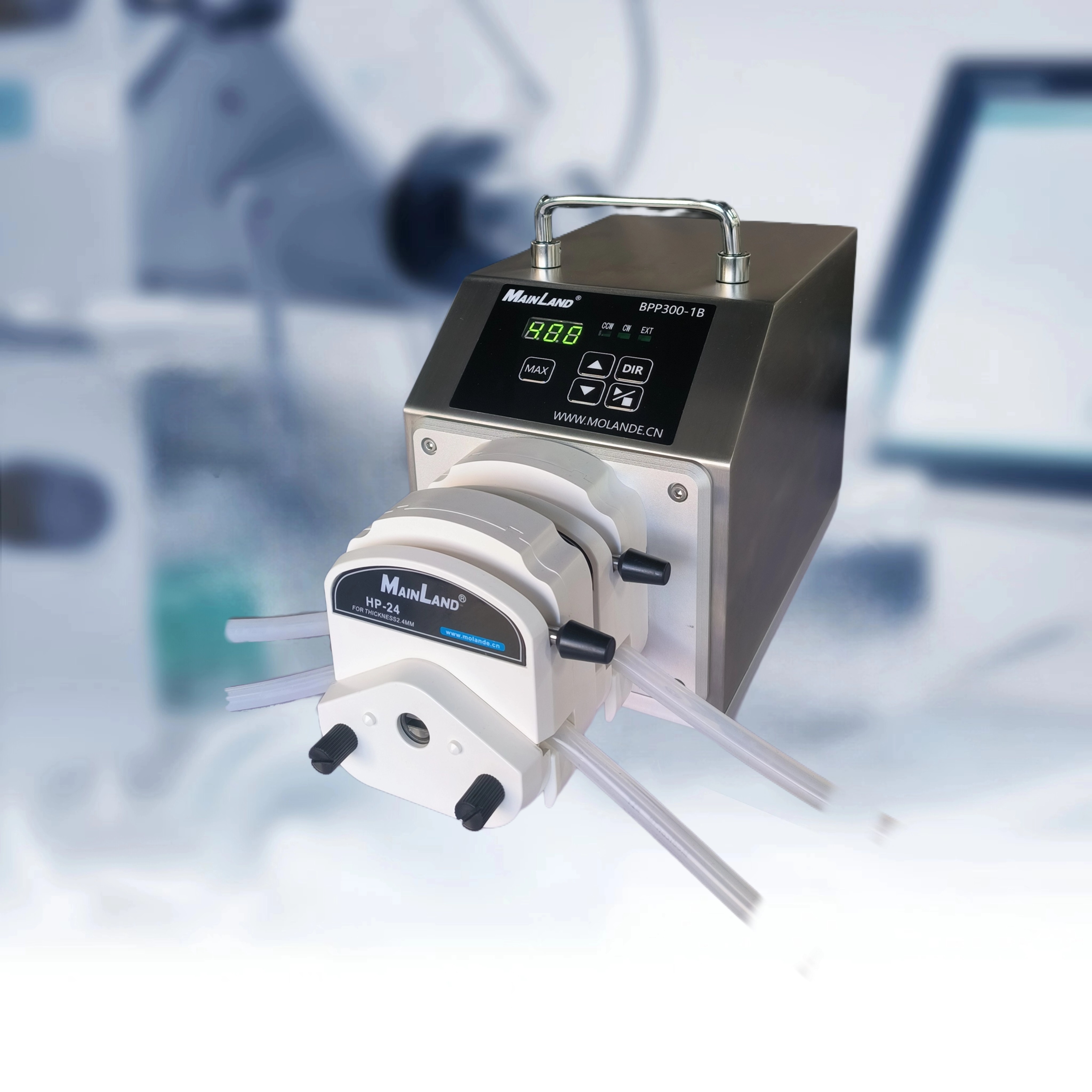

The peristaltic pump plays an indispensable and important role in conveying ink materials such as adhesives, resins, paints, inks, pigments, hydrogen peroxide, etc.

The peristaltic pump can accurately transport various types of high viscosity ink without the need for one-way valves and filtering devices. It can freely change the conveying direction, with a lift of up to 10 meters and a repeatability accuracy of ± 1%. It can be fully used as an ink pump. The peristaltic pump effectively solves the problems of ink splashing from the ink bottle, dirtying the working environment, and inaccurate ink measurement when filling ink. Currently, more and more customers have replaced diaphragm pumps with peristaltic pumps.

Application Cases

Corrugated paper packaging line, ink machine transmission, pumping adhesive, resin, paint, ink, pigment, hydrogen peroxide and other ink materials.

Specific Cases

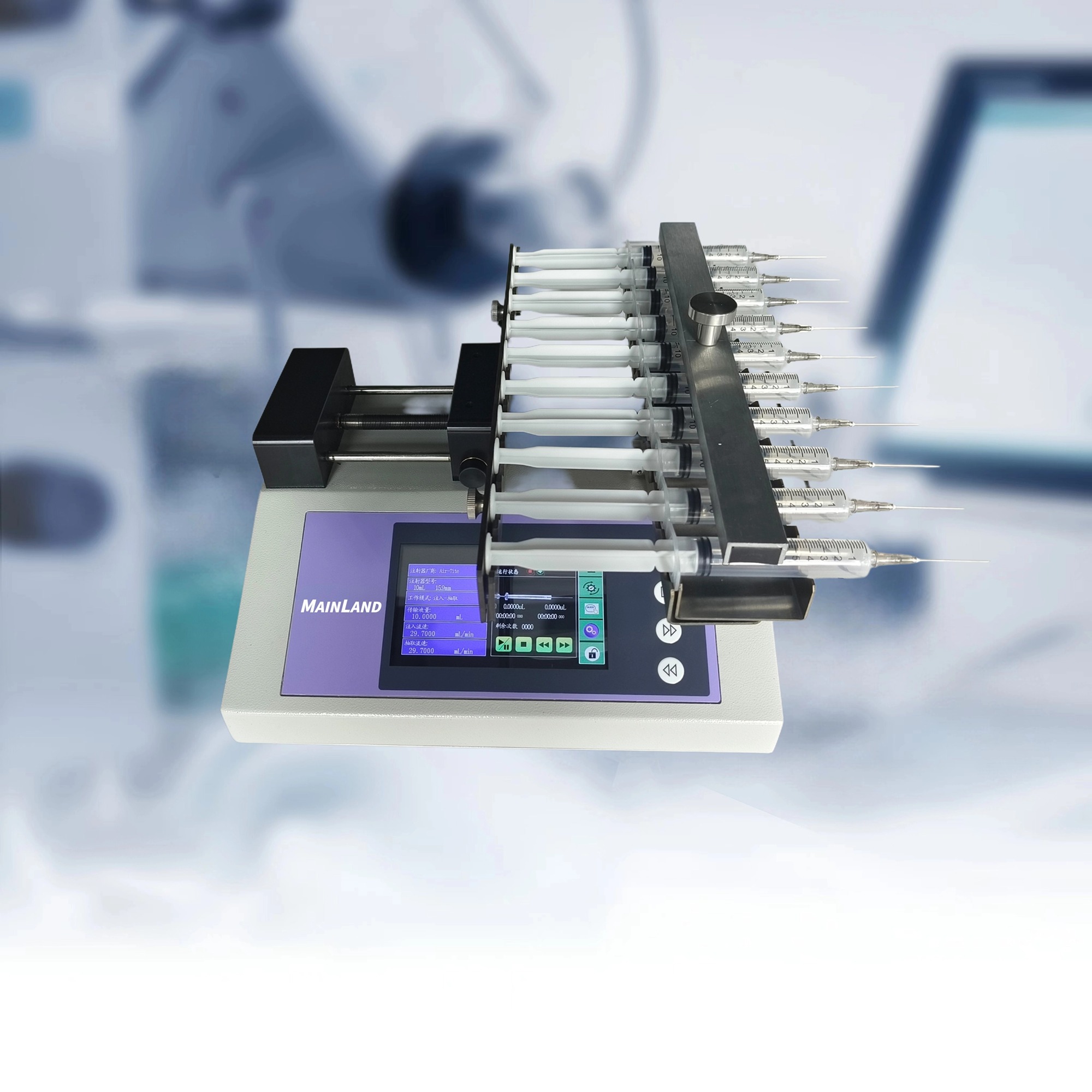

During the high-speed inkjet printing process, the inkjet printer needs to continuously transport ink to the nozzle, and the ink in the ink cartridge will continue to decrease. To ensure a continuous supply of ink, the ink tube is usually inserted into an external ink bucket and pumped to transport the ink to the secondary ink cartridge.

Previously, diaphragm pumps were often used as ink transfer pumps or to collect and discharge waste ink. Although pumps are cheap, for some solvent based or high viscosity inks, they can easily cause damage to the pump or unstable flow during transportation, as well as problems such as residual ink corners inside the pump.

After replacing the peristaltic pump, relevant issues were avoided. It can circulate and transport various water-based and solvent based inks and inks, and can also maintain ink pressure in the ink path.

Home

Home Tel

Tel Product

Product